A Peterborough Based Startup Has Launched A Device That Could Revolutionize Laboratory Systems

/A Made in Peterborough device is set to become an essential component in medical laboratories around the world. Trent University-based Lab Improvements is launching the CapTrack, an innovative, benchtop medical specimen capping and archiving device into the U.S. market.

CapTrack is the brainchild of local entrepreneurs Alex Bushell, 28, and Steve Wright, 56, who have more than two decades of combined experience in the design, installation and servicing of lab automation systems around the world.

From left: Peterborough Innovation Cluster's Rosalea Terry & Mike Skinner; Lab Improvement founders Alex Bushell & Steve Wright

Bushell and Wright saw a need for a compact, affordable solution for labs that could not justify a full-scale automation system.

“While small labs face many of the same issues as larger ones, the traditional automation systems used by high volume labs are not practical for smaller facilities, such as those found in hospitals," says Bushell.

The CapTrack is a portable device that manages refrigerated inventory and caps specimen tubes for medical laboratories. "Our patented technology uses a combination of robotics, process control and software that saves time and money while reducing risk and increasing the quality of laboratory results," says Wright.

Adds Bushell: "Our device allows for smaller labs to process samples automatically, reducing the risk of sample contamination and decreasing staff exposure to blood borne pathogens and repetitive strain injuries. We like to refer to the CapTrack as a ‘co-bot’, meaning a machine that works collaboratively with lab technicians to make their jobs easier, safer and more efficient. It does not replace them."

Bushell and Wright have been working out of the Innovation Cluster's incubator The Cube at Trent University for the past two years. Along with their team of five employees, the duo have taken the CapTrack from a bright idea to market readiness.

"Alex and Steve have had access to our incubation space located at Trent University as well as our knowledge partners and business experts who provided networking, patent application help and strategic planning," says Rosalea Terry, Entrepreneurship & Marketing Coordinator at the Innovation Cluster.

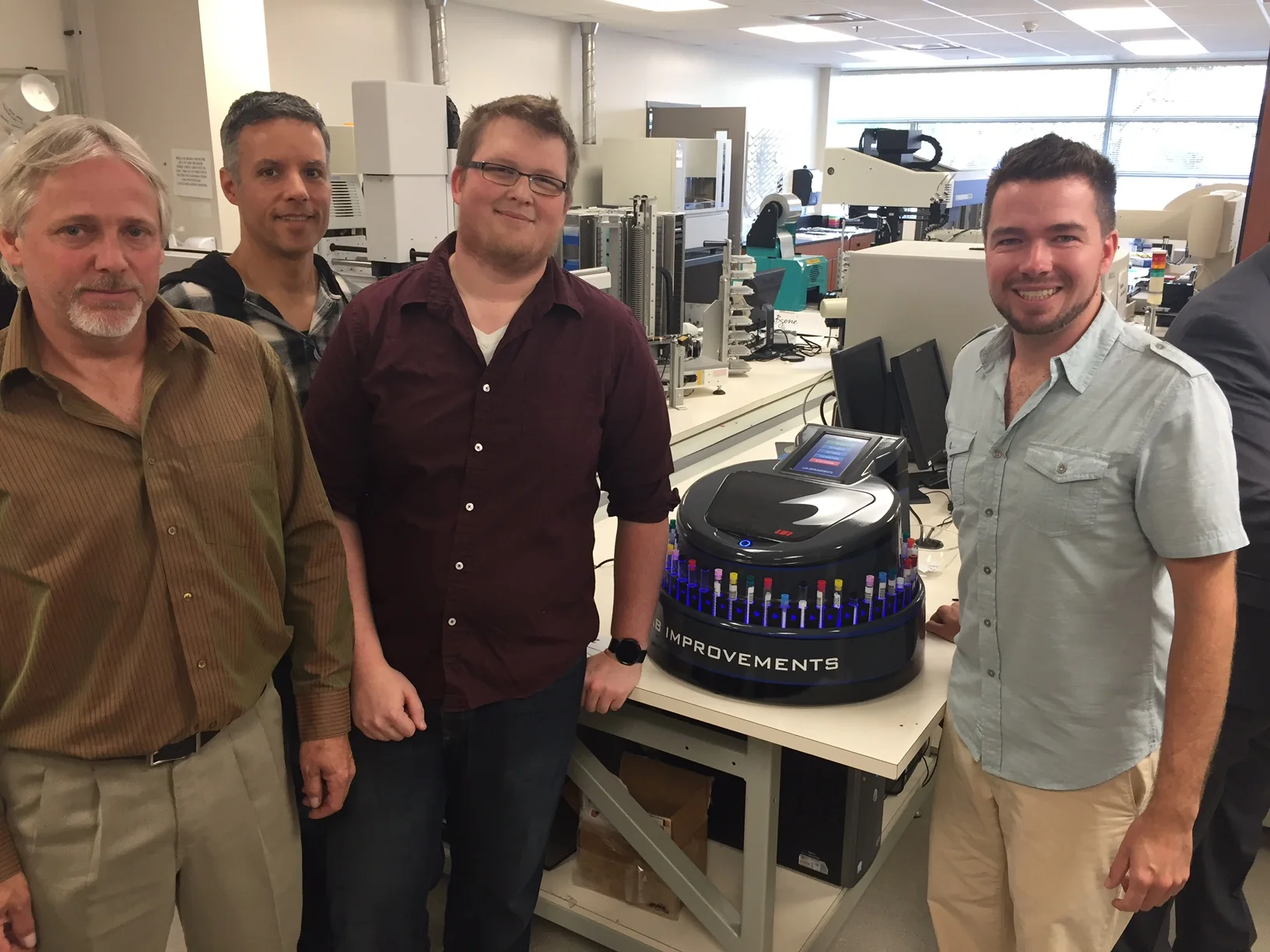

Members of the Lab Improvements team pictured at Trent University's The Cube